- More than 60 years of product development experience

- Optimize alloy, heat treatment, extrusion design and process molding procedures and provide structural solutions at the lowest installation cos

- Customer satisfaction & Best Quality

- We will meet customer’s requirements of High strength alloy/Extrusion/Forged Products

- World-Best Metal Business

- SeAH A&D, which secures and leads cutting-edge technology boasts the highest quality.

- Current location

- Product

- Production capability

As a producer of a wide variety of hard alloy products in Korea, SeAH Aerospace & Defense is more than capable of satisfying

customers requirements for extruded and forged hard alloy products due to its extensive experience and innovative technology.

The technology of SeAH Aerospace & Defense, combined with the production capabilities of SeAH’s plants worldwide,

will satisfy customers requirements for extruded and forged products.

SeAH Aerospace & Defense’s R&D department helps customers select optimal alloy products that can meet their requirements.

Alloys

| 1xxx Series | 1050 | 1070 | 1100 | ||

|---|---|---|---|---|---|

| 2xxx Series | 2007 | 2011 | 2012 | 2014 | 2014A |

| 2017 | 2024 | 2026 | 2214 | 2219 | |

| 2618 | 2618A | ||||

| 3xxx Series | 3003 | ||||

| 4xxx Series | 4032 | AHS1 | AHS2 | A332 | A356 |

| AP2 | 4045 | ||||

| 5xxx Series | 5052 | 5056 | 5083 | 5086 | 5AAA |

| 5356 | 5454 | 5456 | |||

| 6xxx Series | 6005 | 6013 | 6020 | 6042 | 6061 | 6063 | 6066 | 6070 | 6082 | 6101 | 6106 | 6262 | 6262A | 6351 |

| 7xxx Series | 7001 | 7003 | 7050 | 7055 | 7075 |

| 7085 | 7129 | 7150 | 7175 | 7475 | |

| TH72M | CE75 | CE76 |

CE75, CE76 – Specially Designed for consumer electronics

Ability to produce customer-specific alloys

Temper

| Non-Heat Temper | F |

|---|---|

| H111, H112, H32, H34 | |

| Heat Temper | O |

| T3, T351, T3510, T3511 | |

| T4, T4(BD), T451, T4510, T4511 | |

| T5 | |

| T6, T6(BD), T62, T651, T6510, T6511 | |

| T7, T73, T7351, T73510, T76, T76510, T76511 | |

| T8, T81, T851, T8510, T8511 | |

| T9 |

ASTM, AMS Standard specification quality assurance available

| Aerospace and profile | ||

|---|---|---|

| Maximum Circle Size Inch | 10.30 | inch |

| Minimum Thickness | 0.050 | inch |

| Minimum Wt/ft | 0.143 | lbs/ft |

| Maximum - T Temper Length | 335 | inch |

| Maximum O Temper Length | 315 | inch |

| Thick to Thin Ratio | 4:1 | |

| Rod & Bar | Cold Finished | Extruded | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2014, 2024, 7075 | 2011-T3, T8 | 6061, 6082 | 2014, 2024 | 6061, 6082 | ||||||||

| -Tx51, | 6020-T8,T9 | -Tx51 | 7075 | T4, T6, Tx511 | ||||||||

| T6(BD), T4(BD) | 6262-T9 | T6(BD), T4(BD) | -T4,T6,Tx51 | |||||||||

| Type | Thick. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |

| Rod | DIA | 12.7 | 63.5 | 12.7 | 63.5 | 12.7 | 66.7 | 12.7 | 108.0 | 12.7 | 144.8 | |

| Sq. | Thick. | 12.7 | 50.8 | 12.7 | 2.25 | 12.7 | 95.3 | 12.7 | 114.3 | |||

| Bar | Width | 12.7 | 38.1 | 38.1 | 152.4 | 203.2 | ||||||

| 15.9 | 44.5 | 44.5 | 152.4 | 203.2 | ||||||||

| 19.1 | 50.8 | 50.8 | 158.7 | 203.2 | ||||||||

| 25.4 | 76.2 | 76.2 | 165.1 | 203.2 | ||||||||

| 31.8 | 76.2 | 76.2 | 171.5 | 203.2 | ||||||||

| 38.1 | 66.7 | 76.2 | 177.8 | 203.2 | ||||||||

| 44.5 | 57.2 | 63.5 | 190.5 | 203.2 | ||||||||

| 50.8 | 177.8 | 203.2 | ||||||||||

| 57.2 | 158.8 | 203.2 | ||||||||||

| 63.5 | 142.2 | 203.2 | ||||||||||

| 76.2 | 119.4 | 203.2 | ||||||||||

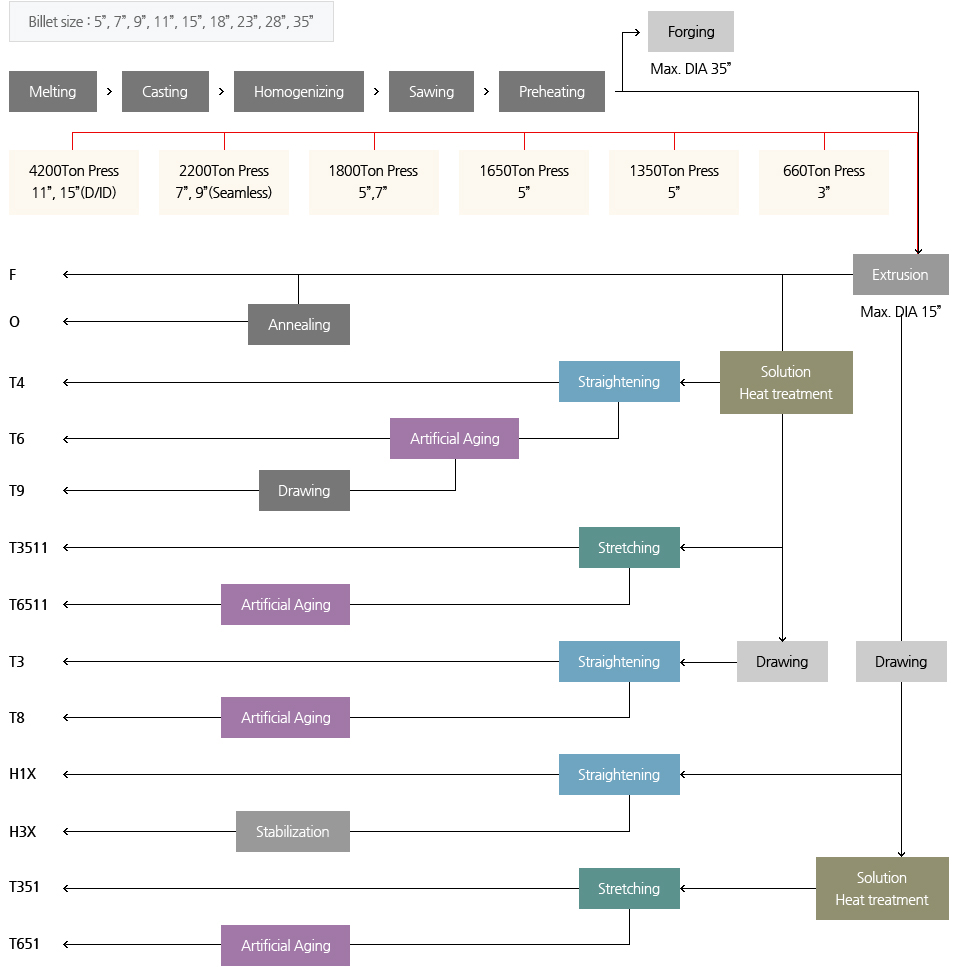

Process Flow Path(in General)

- Raw material

- Melting

- Chemical Analysis

- Casting

- Homogenization

- Billet Cutting

- Extrusion

- Process Cutting

- Solution Heat treatment

- Stretching

- Final Cutting

- Arificial Aging

- Inspection (Mechanical, Macrostructural, Dimensional etc.)

- Packing