- More than 60 years of product development experience

- Optimize alloy, heat treatment, extrusion design and process molding procedures and provide structural solutions at the lowest installation cos

- Customer satisfaction & Best Quality

- We will meet customer’s requirements of High strength alloy/Extrusion/Forged Products

- World-Best Metal Business

- SeAH A&D, which secures and leads cutting-edge technology boasts the highest quality.

- Current location

- Product

- R&D Innovation

Our product development team boasts of over 60 year of experience.

Our engineering capability optimizes procedures for alloy heating and extrusion design, processing, and shaping and offers

structural with minimal installation cost. And in response to the advanced market and changed customer requirements,

we are focusing on developing new alloys and processes to manufacture customized products.

Providing superior machinability and anodizing response through CFRB

We developed our best practice in 2xxx, 6xxx, and 7xxx alloys to get the excellent machinability and anodizing response for the good finish through CFRB(Cold Finished Rod & Bar)

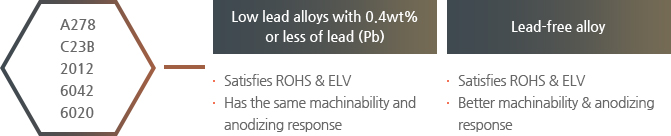

- 01. Contribute to low-lead and lead-free alloy market for replacing leaded alloy

-

- Alloys with 0.4wt% of Pb or less(A278,C238, and 6042) and Lead-free alloy(6020) to replace Alloys (C278, 2011, and 6262)

< Reference 1 >

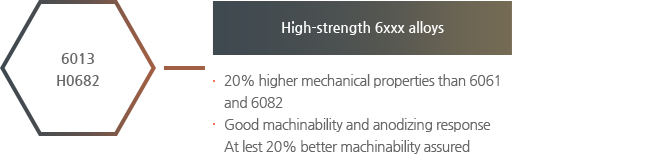

- 02. High-strength 6xxx series alloys for better finish and machinability

-

- Alloys 6013 and H0682, at least 20% stronger than existing 6061 and 6082 with better machinability and anodizing response.

< Reference 2 >

- 03. Aluminum rings & Cogging bars

-

- Cogging bars with structures and mechanical properties made better than existing cast billets through latger-than-8 OD rods,

stree-free aluminum rings up to outer diameter of 2.7m through large billets(35 OD)

- Cogging bars with structures and mechanical properties made better than existing cast billets through latger-than-8 OD rods,

- 04. Big billets for forging

-

- We provide forging billets for large products, on which ultrasonic testing is performed according to ASTM B 594 and

AMS STD 2154-Hydrogen gas is restricted under 0.11cc/100g up to 35 OD.

- We provide forging billets for large products, on which ultrasonic testing is performed according to ASTM B 594 and

- 05. Component development using big high-strength billets in 7xxx series

-

- In keeping with the recent trend of larger components, we produce billets in 21, 22, 28 and 35 in 7xxx series,

larger than the biggest(15) of existing billets through die forging/free forging, contributing to sizing up components.

- In keeping with the recent trend of larger components, we produce billets in 21, 22, 28 and 35 in 7xxx series,

< Reference 1 >

< Reference 1 >

< Reference 2 >

< Reference 2 >